- Home

- Blog

- Custom Patches

- What Are Embroidered Patches?

Embroidered Patches: History, Types, Backings, Borders, Design & Cost Guide

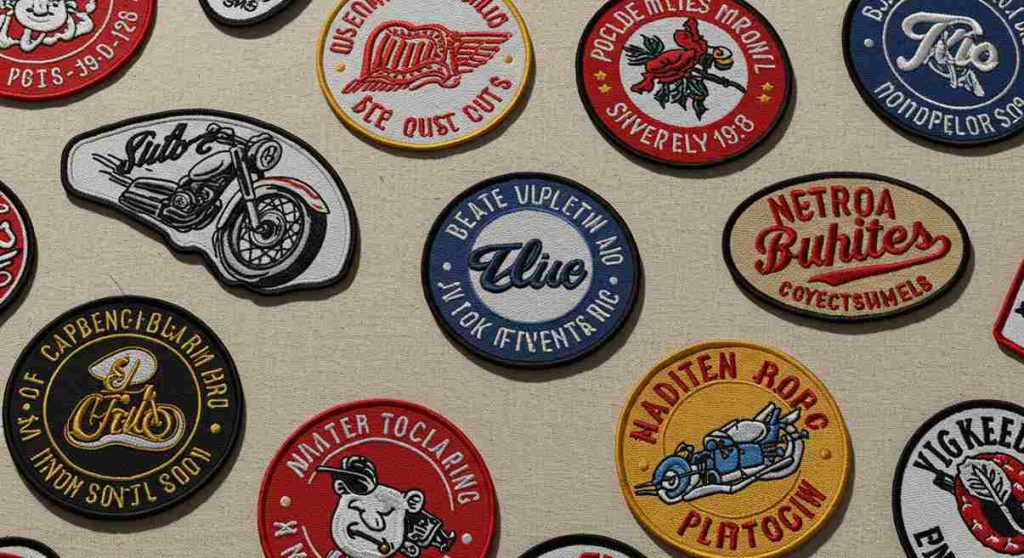

Embroidered patches are timeless accessories that combine style, function, and identity. They are used on uniforms, fashion, corporate branding, and personal items, offering durability with a handcrafted look.

Their raised, textured design stands out, making them ideal for logos, lettering, and decorative details. Over centuries, embroidered patches have evolved from ancient fabric repairs to powerful symbols of recognition, pride, and expression.

Today, they remain one of the most popular patch types due to their versatility, quality, and professional appearance. This guide explores their history, types, manufacturing process, cost factors and best supplier for embroidered patches.

What Are Embroidered Patches?

Embroidered patches are decorative cloth badges created by stitching thick, colorful threads onto a fabric base. This embroidery process gives them a textured, raised, and dimensional look that feels handcrafted and premium. Because of their distinct appearance, they are widely used for uniforms, branding, personal style, and memorabilia.

The fabric backing, often cotton or twill, serves as the foundation where the threads are stitched. This strong base provides stability and ensures the patch holds its shape over time. The use of thicker embroidery threads adds depth, making designs stand out clearly and attractively.

These patches can be attached in different ways depending on the purpose. Sewing offers a permanent and professional finish, while iron-on adhesive allows for quick application with heat. Both methods make embroidered patches versatile for clothing, hats, jackets, and workwear.

Durability is one of their strongest features. Sturdy threads and fabrics make embroidered patches resistant to wear and tear, which is why they remain popular for uniforms, sports teams, and heavy-use garments.

The making process begins with digitizing the design. Once prepared, embroidery machines precisely stitch threads into the fabric backing, interlocking each thread to form the image. The result is a durable, high-quality patch that highlights logos, text, or artwork with clarity and long-lasting appeal.

History of Embroidered Patches

Embroidered patches have a deep history that spans thousands of years. Their journey began in ancient China between the 5th and 3rd centuries BC. At first, hand-sewn fabric was used to repair torn clothing, but this practical approach quickly evolved into an art form.

People began adding stitched patterns on garments and tapestries to show wealth, social status, and beauty. Embroidery became both functional and symbolic, marking the earliest form of patches.

By the 18th and 19th centuries, patches gained prominence in the military. Soldiers wore embroidered insignia on uniforms to identify ranks, divisions, and achievements. This practice brought structure and recognition to armies worldwide. At the same time, the Industrial Revolution transformed production.

The invention of the first embroidery machines, and later Isaac Groebli’s famous Schiffli machine, made embroidery faster, more consistent, and more affordable. These advancements spread patch usage far beyond elite classes and made them standard in military gear.

The 20th century marked the modern era of embroidered patches. After World War II, military surplus patches became available to the public. Civilians began collecting and wearing them, and patches entered mainstream culture. In the 1950s and 60s, biker clubs adopted large back patches as emblems of pride and identity. By the 1970s and 80s, patches were part of fashion, music, and counterculture movements, appearing on denim jackets, bags, and hats.

Today, embroidered patches are everywhere. They are used by sports teams, scouts, corporations, military, and fashion brands. Modern embroidery machines and digitized design software allow for highly detailed patterns, 3D embroidery, metallic threads, and even glow-in-the-dark elements.

What started as simple fabric repairs in ancient China has evolved into a global symbol of identity, branding, and self-expression, keeping embroidered patches timeless and relevant across centuries.

Types of Embroidered Patches

Embroidered patches are mainly available in two distinct types, each offering unique qualities to match different design needs and style preferences.

Standard Embroidered Patches

Standard embroidered patches are the most common and versatile option. They are made by stitching flat embroidery threads onto a fabric base, creating a durable and textured surface. These patches deliver a classic, professional appearance and are widely used for uniforms, branding, sports teams, and fashion items. Their timeless look makes them the first choice for most applications.

3D Puff Embroidered Patches

3D puff embroidered patches add depth and dimension by stitching over foam material, giving designs a raised, three-dimensional effect. This technique enhances logos, lettering, and bold graphics, making them more eye-catching.

These patches are especially popular in fashion, sportswear, and caps where a standout, modern style is required. Their unique texture provides a premium look that instantly grabs attention.

Backing Options for Embroidered Patches

Backing options determine how embroidered patches attach to garments, offering flexibility, durability, and ease of use depending on application needs.

Iron-On Backing

Iron-on backing uses a heat-activated adhesive that bonds the patch to fabric. It allows quick and easy application with a household iron. The attachment is permanent and secure, making it ideal for casual wear, light jackets, or personal items where convenience is important.

Sew-On Backing

Sew-on backing is the traditional method that requires stitching the patch directly onto the garment. This approach provides the most durable attachment, ensuring the patch stays in place even under heavy use.

It offers a professional finish and is the best choice for uniforms, workwear, and items exposed to frequent washing.

Velcro Backing

Velcro backing features hook and loop fasteners that make patches removable and interchangeable. This flexibility allows users to switch designs without replacing the garment. It is especially popular for tactical gear, military uniforms, and outdoor equipment.

Velcro-backed patches are easy to wash and maintain since they can be detached before cleaning and reattached afterward.

Adhesive Backing

Adhesive backing works with a peel-and-stick layer applied to the back of the patch. It offers temporary or semi-permanent attachment, making it useful for testing placement or short-term use.

This option works best on smooth surfaces like bags, notebooks, or accessories where sewing or ironing is not practical.

Border Options for Embroidered Patches

Border style defines the finishing of embroidered patches. The right choice improves durability, appearance, and ensures the design stands out with a clean, professional look.

Merrowed Edge (Overlock Border)

Merrowed edge is the most common and traditional border option. The edges of the patch are wrapped with thread, creating a neat, raised outline. This finish works best for circular, square, or simple-shaped patches.

It adds extra durability, prevents fraying, and gives a strong, professional appearance suitable for everyday use.

Heat-Cut Edge (Laser-Cut Border)

Heat-cut edge is created by cutting the patch with a laser or hot knife. This method is ideal for irregular or complex shapes where merrowed edges are not possible.

The border remains flat and follows the exact outline of the design. It is widely used for fashion items and custom logo patches.

Design Considerations for Embroidered Patches

Designing embroidered patches requires attention to detail. Size, color, and complexity all impact clarity, cost, and overall quality. Careful planning ensures a professional result that matches your design needs.

Size Guidelines

The minimum size for embroidered patches is usually one inch, but patches that small are best suited for simple name tags. Logos and detailed artwork rarely fit well into a one-inch patch. The maximum size can go up to twelve inches, which is commonly used for large back patches.

The most popular sizes for logo patches are three to four inches. At this range, details appear clearly, and text remains easy to read.

Color Selection

Most embroidered patches look best with six to twelve thread colors. For brand consistency, Candle thread color matching helps achieve accurate results. It’s also important to create strong contrast between the background and design so every detail stands out.

Design Complexity

Simple designs produce sharper embroidery, cleaner thread definition, and lower costs. Fine details require a minimum size, usually three to four inches, to keep logos clear. For small text, sans-serif fonts provide the best legibility.

High-quality vector files make logo adaptation easier, helping digitizers create accurate stitch files. Low-quality artwork complicates the process and may reduce embroidery accuracy.

Manufacturing Process of Embroidered Patches

The manufacturing process of embroidered patches involves several precise steps, each ensuring durability, clarity, and professional results. From design to final inspection, every stage plays a vital role in quality.

Design Digitization

The first step is Embroidery digitizing. Artwork or logos are converted into a digital embroidery file using specialized software. This file guides the embroidery machine on stitch types, directions, and sequences.

It decides which part of the logo is stitched first and where the process ends. Proper digitization ensures clean outlines, accurate details, and efficient production. A strong digitized file is the foundation of every embroidered patch.

Thread Selection

After digitization, the right threads are selected. Both viscose and polyester threads are widely used, each offering unique benefits.

Viscose delivers a natural sheen and bright colors, while polyester provides extra durability, UV resistance, and wash safety. Choosing accurate colors and weights ensures consistency and matches brand requirements.

Base Material Preparation

Once threads are finalized, the backing fabric is prepared. Twill fabric is the most common choice because it is durable and supports embroidery well. Felt fabric is also used but less frequently, as it suits specific designs.

The fabric is carefully cut to size, ensuring the embroidery area is smooth and ready. A strong base allows the stitched design to stand out clearly.

Embroidery Production

With digitized files, thread colors, and fabric prepared, production begins. The embroidery machine follows the programmed instructions to stitch designs with precision. Every thread is placed carefully to maintain accuracy and balance.

Quality control is monitored during production to reduce errors and keep the design consistent. This stage brings the artwork to life as a finished embroidered patch.

How Do Embroidery Machines Work?

Embroidery machines bring digitized designs to life with precision. Guided by specialized software, the machine directs needles and threads to stitch exact patterns onto fabric. Multi-head machines ensure consistency and speed for bulk production. Their automation makes embroidered patches durable, accurate, and scalable. For an in-depth guide, read How Do Embroidery Machines Work?.

Finishing

After embroidery is complete, finishing work starts. Excess threads are trimmed to keep the design neat. Patches are then cut to size using merrowed or laser-cut edges.

The chosen backing, whether iron-on, sew-on, Velcro, or adhesive, is applied at this stage. Finishing ensures each patch is polished, durable, and ready for application. A clean finish makes the patch professional and long-lasting.

Quality Inspection

The last step is quality inspection. Each patch is checked for thread consistency, correct colors, and overall accuracy. To maintain quality, more patches are produced than required, allowing defective pieces to be removed.

This ensures customers receive the exact quantity ordered with the highest standards maintained. A strict inspection process guarantees professional results in every batch.

Quality Factors to Consider

Several quality factors define the durability, appearance, and overall performance of embroidered patches. Paying attention to these ensures a professional and long-lasting result.

Thread Quality

Thread quality plays a central role in the final look. Candle threads are popular for their bright colors, smooth sheen, and cost-effectiveness. Viscose threads offer a soft texture and excellent finish for premium designs.

Cotton threads provide a natural and eco-friendly option but are rarely used in bulk production because they lack the durability of viscose or polyester alternatives.

Stitch Density

The density of stitches affects both strength and appearance. An optimal length of three to four millimeters ensures durability and balanced coverage.

If density is too low, the patch looks thin and weak. If it is too high, the patch may pucker, feel stiff, and lose flexibility. Proper density creates a neat and lasting embroidery finish.

Stitch Count

Stitch count determines how much detail and coverage a patch design can achieve. Higher stitch counts allow for sharper lines, finer details, and bold textures. However, more stitches also increase production time and cost.

Lower stitch counts reduce cost but may compromise clarity in complex designs. Balancing stitch count with design complexity ensures a professional, high-quality embroidered patch.

Embroidery Coverage

Embroidery coverage refers to how much surface area of a patch is stitched with thread. High coverage creates bold, dense designs that stand out, while low coverage leaves more fabric visible, offering a lighter and breathable finish. Balancing coverage with stitch density ensures patches remain durable without looking stiff.

Applications and Uses of Embroidered Patches

Embroidered patches are versatile and serve multiple purposes across industries, fashion, and organizations. They combine identity, branding, and style while remaining durable and long-lasting.

Corporate Branding

Businesses use embroidered patches to strengthen professional identity. Employee uniforms often feature custom patches that display logos clearly.

Companies also distribute patches as promotional merchandise and include them in trade show giveaways. Some brands create loyalty programs where customers receive embroidered patches as exclusive rewards, increasing recognition and engagement.

Organizations and Clubs

Clubs and organizations rely on embroidered patches for visibility and pride. They identify members, highlight achievements, and commemorate special events.

From scouting groups to social clubs, patches bring a sense of belonging. They are also produced for fundraising, helping organizations raise awareness and generate support while offering tangible items people value.

Fashion and Personal Style

In fashion, embroidered patches make bold style statements. Jackets become personalized with detailed designs stitched onto the back or sleeves. Bags and hats gain character when decorated with unique patches.

Vintage and retro looks often rely on embroidered patches, blending nostalgia with modern style, making them timeless accessories across fashion trends.

Sports and Recreation

Sports teams and recreational groups use patches for unity and recognition. Team jerseys feature embroidered identifiers, while leagues adopt patches to show official participation. Tournaments often include commemorative patches as keepsakes.

Sponsors also appear on patches, giving brands visible placement and teams financial support, making patches a vital part of sports culture.

Care and Maintenance of Embroidered Patches

Proper care keeps embroidered patches vibrant, durable, and long-lasting. Following the right washing, drying, and storage practices ensures they maintain their shape and appearance over time.

Washing Instructions

Wash garments with embroidered patches in cold water to avoid color bleeding. Use a mild detergent that protects thread strength and prevents fading. Never apply bleach, as it can damage both fabric and threads. Turn clothes inside out before washing to protect the patch surface from friction during the cycle.

Drying Guidelines

Air drying is the safest method to preserve patch quality and prevent heat damage. If using a dryer, select the lowest heat setting. Keep items away from direct sunlight for long periods, as UV rays fade colors. Remove garments slightly damp to prevent over-drying and keep patches flexible.

Storage Tips

Store embroidered patches in a cool, dry environment. Avoid folding garments over the patch area to prevent creasing. Place tissue paper between stacked items to reduce pressure and protect stitching. Always keep patches away from prolonged sunlight to maintain vibrant colors and crisp thread definition.

Cost Factors of Embroidered Patches

The cost of embroidered patches depends on several factors, including quantity, size, complexity, and special features. Understanding these elements helps in planning orders effectively.

Quantity

Larger orders lower the per-unit price, making bulk production cost-effective. Most suppliers require a minimum order of fifty to one hundred pieces. At Nexus Patches, even small runs are possible, and we create as few as ten patches. Setup costs, including digitizing and threads, are charged once per design.

Size and Complexity

As patch size increases, stitch count rises, leading to higher production costs. Larger patches require more fabric, threads, and machine time.

Complex designs add further expense because frequent thread changes demand extra labor. Color count also affects pricing, with more shades increasing both stitching time and overall cost.

Special Features

Premium options raise costs depending on the material or effect. Metallic threads create a shimmering finish but come with higher pricing. Three-dimensional puff embroidery adds texture and depth, making it more labor-intensive. Glow-in-the-dark threads also increase pricing while delivering unique, standout results.

Choosing the Right Supplier

Selecting the right supplier ensures your embroidered patches meet high standards of quality, consistency, and timely delivery. A reliable partner saves time, cost, and reduces production risks.

Quality Standards

Quality is the first factor to check. Always review a supplier’s portfolio to examine their past work. Ask about the type of threads and backing materials they use to confirm durability. Verify their production capacity and equipment to ensure they can handle both small and large orders without compromising quality.

Service Factors

Strong customer service makes the process easier. The right supplier offers artwork and digitizing assistance to perfect your design before production. They maintain clear communication and respond quickly to inquiries.

Delivery timelines should be reliable and realistic. Minimum order requirements must also align with your needs, whether you need small runs or large-scale production.

Pricing Structure

Pricing transparency is essential for trust. A good supplier provides a clear cost breakdown, explaining charges for digitizing, threads, and production. There should be no hidden fees at any stage of the process. Volume discounts should also be available, offering better rates when larger quantities are ordered.

Why Nexus Patches?

Nexus Patches stands out as a trusted supplier by combining quality, speed, and service. We use premium materials and maintain a strong portfolio of past work. Our team can handle both small and large orders with ease.

We provide free design and digitizing support, often preparing files the very next business day for client approval. Delivery is quick, with most orders completed within five to fifteen business days depending on quantity. Smaller runs, such as one hundred to five hundred patches, are usually ready within six days.

As a reliable USA patch supplier, we serve clients nationwide and beyond. Our pricing is transparent with no hidden fees, and customers can order any quantity they need. We also offer worldwide shipping, making it easy for businesses and individuals around the globe to access our high-quality custom embroidered patches. Larger orders receive generous discounts, making Nexus Patches the ideal partner for reliable, professional results.

Embroidered Patches Comparison with Others

Embroidered patches are classic and versatile, but other patch types also exist. Each option has unique qualities, and choosing the right type depends on your design and application needs.

PVC Patches

PVC patches are waterproof, flexible, and capture fine details that embroidery cannot. They suit outdoor and tactical use, while embroidered patches give a more traditional, textured look. For a complete comparison, read our detailed guide on PVC vs Embroidered Patches.

Sublimation/Printed Patches

Printed patches reproduce complex, photo-like designs with unlimited colors. They are ideal for artwork embroidery cannot capture. Embroidered patches, however, provide depth and a handcrafted texture. For more information, see our full guide on Printed vs Embroidered Patches.

Woven Patches

Woven patches achieve higher detail with thinner threads, making them perfect for small text and intricate designs. Embroidered patches, in contrast, add raised texture and dimension. To understand both options, visit our guide on Woven vs Embroidered Patches.

Chenille Patches

Chenille patches use fuzzy yarn for a bold, textured surface, often seen on varsity jackets. Embroidered patches are sharper and more versatile for logos and branding. For a side-by-side analysis, read our detailed guide on Chenille vs Embroidered Patches.

Direct Embroidery

Direct embroidery stitches designs directly onto garments, making logos permanent but less flexible. Once stitched, designs cannot be transferred or replaced. Embroidered patches, however, are removable, customizable, and versatile. For a detailed comparison, see our full guide on Direct Embroidery vs Embroidered Patches to understand key benefits and differences.

Conclusion

Embroidered patches remain one of the most effective ways to showcase identity, promote brands, and add style to garments. Their durability, versatility, and timeless look make them valuable across industries, from corporate uniforms and sports teams to fashion and personal expression.

By understanding their history, design options, backing choices, and production process, you can make informed decisions for your next project. At Nexus Patches, we focus on quality, clear pricing, and fast delivery.

Whether you need small or bulk orders, we provide custom embroidered patches that exceed expectations and bring your designs to life.